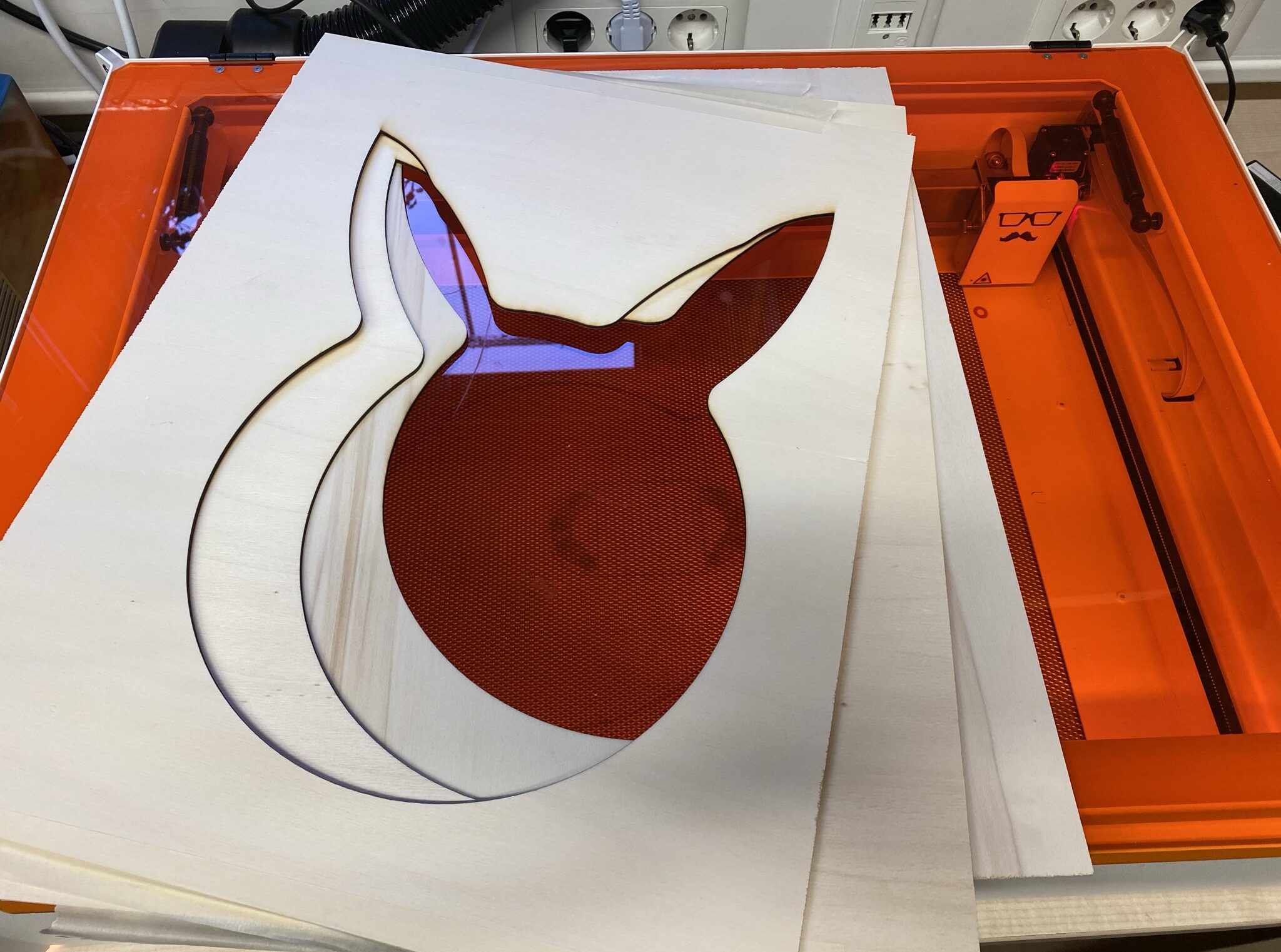

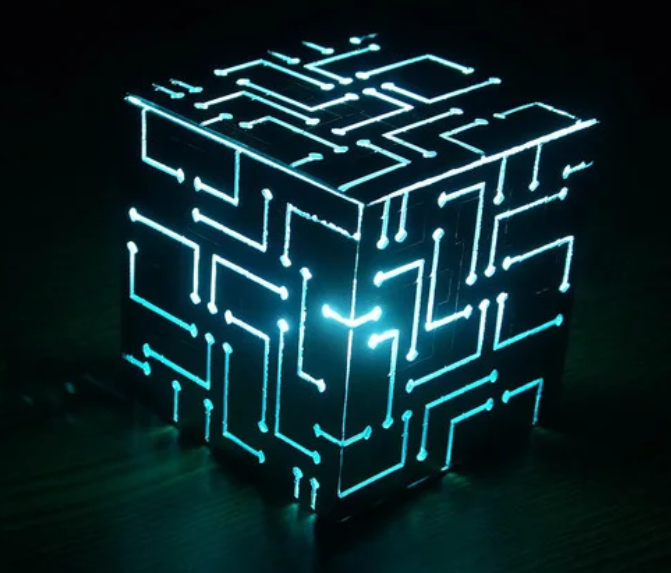

I’d like to have an so called “Alien Cube” as a lamp hanging from my ceiling. And on Thingiverse there is a template for lasercutting one. Link: https://www.thingiverse.com/thing:1805216

But the template is for 10x10x10cm and i want it BIIIIG! My version should be 38cm side length. This Box should then be illuminated by LED stripes and LED-powered light strings. A nice idea. So i redsigned the whole thing added some roundings to the 90° lines and made my template “Kangaroo style” 🙂

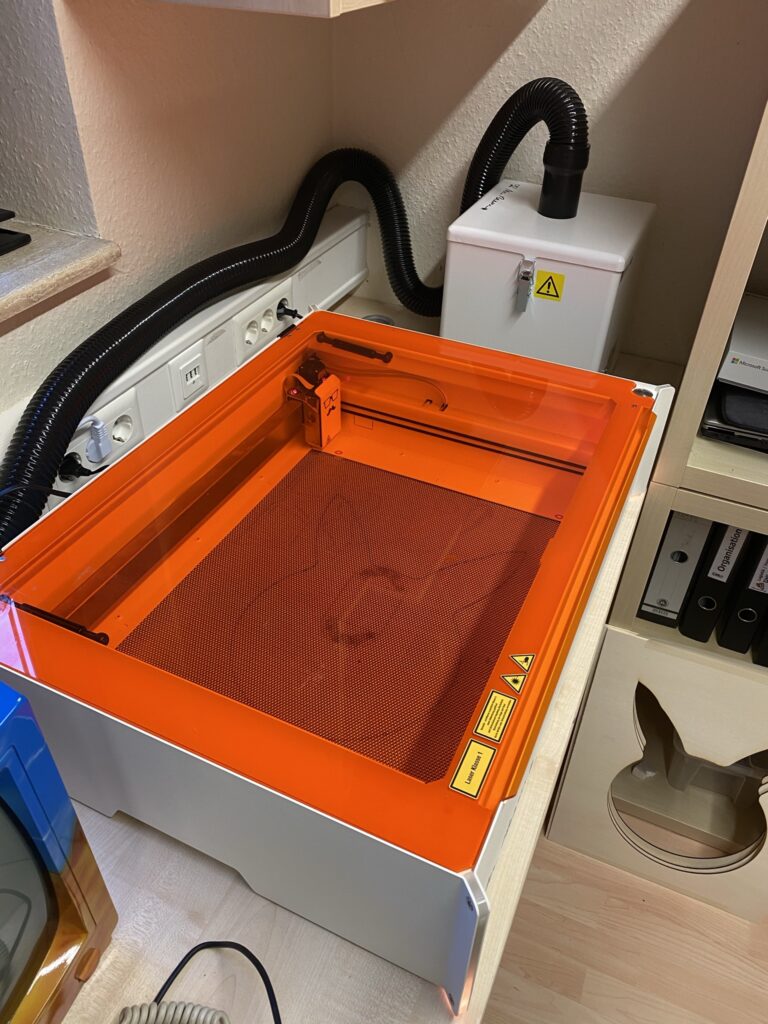

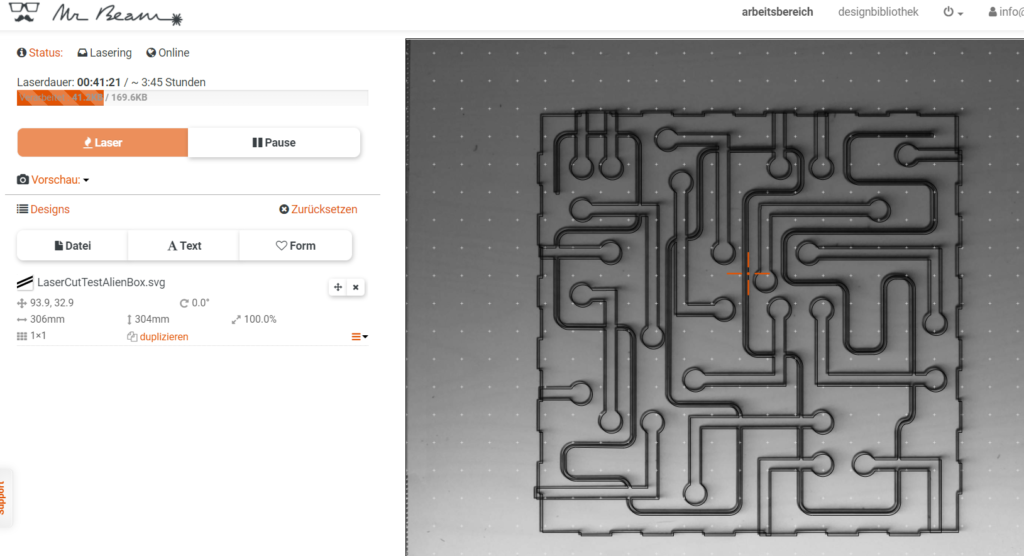

Lastly i cut some poplar plywood with a thickness of 3mm. And it took 5 rounds for the lasercutter to get through the material. And as described on Mr. Beam’s Homepage this lasercutter can cut poplar up to a thickness of 4mm and birch multiplex up to 3mm. So i thought: This will be a fast and nice project with the more stable birch wood. I was so wrong.

My lasercutter is cutting that bloody birch multiplex 3mm plate sind 25 hours now 🙂 Its the 35 time the laser is going around and around and around 🙂 I am cutting 10 Hours a day and it seems that 10 hours are similar to 1mm of cutted wood. I hate birch so very much, i ordered a bunch of poplar hoping those plates will arrive soon 🙂

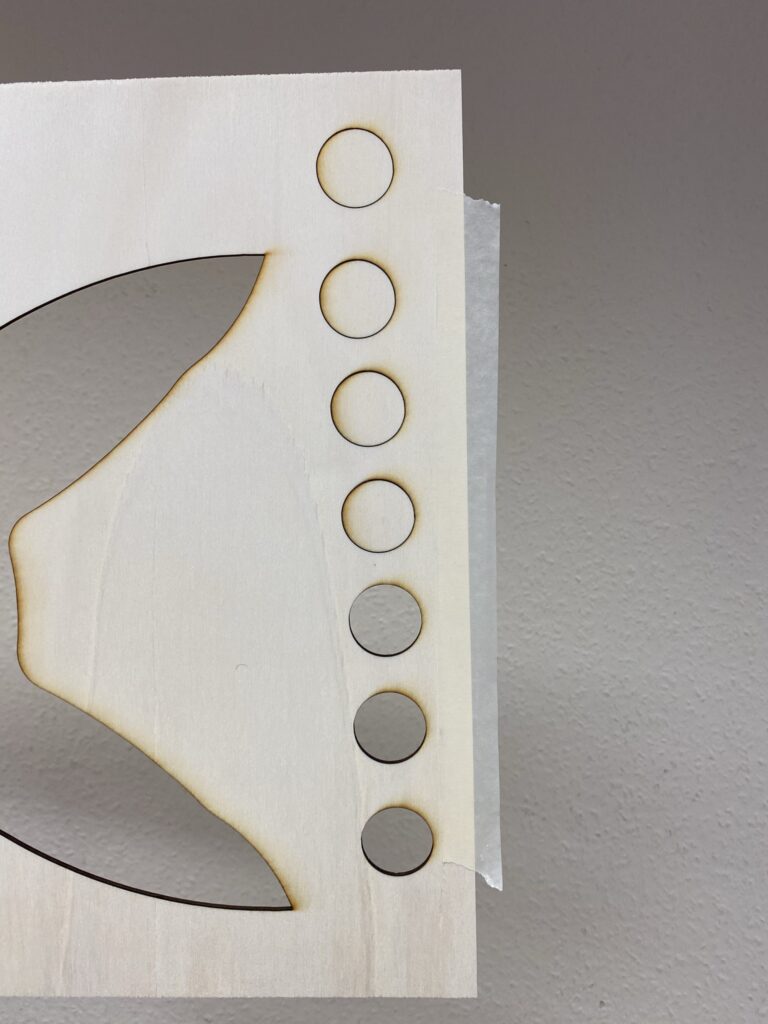

But i want to know how birch multiplex 3mm is cutted, so i stay patient. Normally i demo-cut a few circles on a new material to check how many rounds a cut-through will take. But i forgot this totally. So now i have to wait until i can be sure everything is cutted through. After each cutting-session i open the lid and try to move the cutted pieces but thes still stay in place. Hopefully this gets to an end on the weekend 🙂

After that i will proceed the cut tests with a circle of 1cm and different speeds and power-settings, so i can provide the best setup for cutting birch multiplex with 3mm thickness.